LSY Sonitek Engineering has honed its CNC production capacity and process to meet the requirements of the toughest complex precision-machining projects.We have established and maintain an ideal combination of cross-trained and highly skilled talent; a facility outfitted with top-of-the-line multi-axis milling, grinding, turning and drilling equipment; and lean methodologies using 5S, multiple work cells, and just-in-time strategies and systems.

Our 70,321.42 sq feet machine manufacturing plant features some of the finest CNC machinery available for producing complex parts, machined parts, and assemblies to tight tolerances. All machining centres have full 4th axis capability and produce complex, high-precision components. We have earned international recognition for our precision turning along with complex secondary milling and drilling operations to a broad range of diameters and lengths. We regularly hold tolerances of +/- .0002 where production tolerances are +/- .0005. Make-complete strategies executed through the use of multi-tasking CNC machines and assisted multi-pallet milling machines ensure the fastest cycle times and highest quality.

High-precision machine work requires attention to fine detail, and we keep a close eye on that every step of the way. Our finishing department takes meticulous care deburring, cleaning, assembling, and packaging your order, so your product is not only defect-free, it also meets your high standards and is something we’re proud to have manufactured.

VARIAXIS i-800T - 5-AXIS, MULTI-TASKING MACHINE

|

Spindle: Magazine: Rotary Axes: Feed Axes: |

SAND BLAST POLISH HS-2012 MACHINE

|

|

HIGH SPEED 24,000 RPM CNC MILING MACHINE FANUC ROBODRILL α-21LiB SERIES

|

|

CNC MACHINE MCV-860

|

|

CNC MACHINE QP2033-L

|

Working distance |

CNC MILLING MACHINE-QP2040-L

|

Working distance |

MAZAK CNC TURNING MACHINE

|

Working Distance: |

FANUC ROBOCUT α-CIC SERIES

|

|

SOLID WIRE CUT MACHINE

|

|

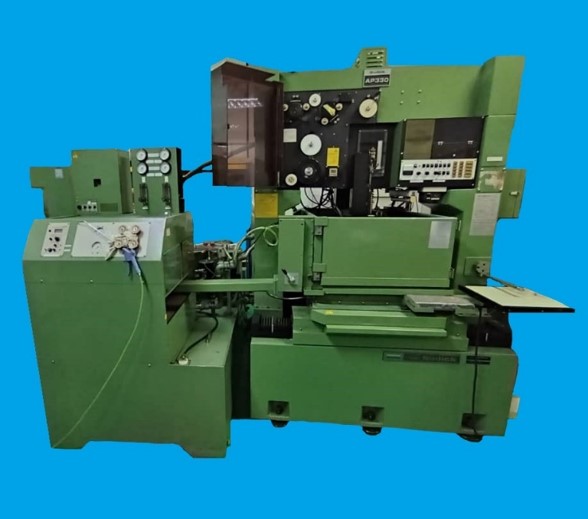

OKAMOTO GRADING MACHINE

|

|

LATHE MACHINE

|

|

SMART FIBER LASER MARKING MACHINE

|

Double heads laser machine is specially for mass production of applique embroidery with less cost, double effigies and better cutting quality. For wood, papers, leather, cloth, resin, acrylics, woolens, plastic, rubber, bamboo and other non-metal materials; this serial apply to cloth, leather, fabric toy, computerize embroidery cutting, electric products. Advantage : Specifications: |

BENDING MACHINE – PPT 100/30

|

Bending machine works on metal materials. Part of on metal plating materials stainless steel, mild steel and aluminium. Specifications : |

BENDING MACHINE – HPS 100/30

|

Bending machine works on metal materials. Part of on metal plating materials stainless steel, mild steel and aluminium. Specifications : |

ZDM-1000BR - BRUSHING AND DEBURRING COMBINATION MACHINE

|

Specifications : |

HAEGER 618 PLUS - HARDWARE INSERTION MACHINE

|

Specifications : |

FIBER HANDHELD WELDING MACHINE TFZS-1500

|

Handheld Laser Welding Machine is a new type of welding method, mainly for the welding of thin-walled materials and precision parts. It can realize electric welding, butt welding, stack welding, sealing welding, etc Specifications : |

| MANUAL MILLING MACHINES

|

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. The integration of milling into turning environments, and vice versa, began with live tooling for lathes and the occasional use of mills for turning operations. Spindle axis orientation : Vertical versus horizontal; Turret versus non-turret Control Manual : Mechanically automated via; Digitally automated Purpose : Toolroom machine versus production machine |

To examine products and materials for defects or deviations from the specifications.