LSY Sonitek Engineering is one of Penang best cable assembly and wire harness companies. So, we handle electronic wiring harness, signal wiring harness, automobile wiring harness, power cables, and many others.We do not only run wire harness production; we also assemble, design custom wiring, and provide an efficient delivery route.We also supply and distribute custom cable assembling and wire harness that turns your tailored design into a workable harness that meets your customers demands.So, we ensure to meet your specific needs whether you are a contract manufacturer, integrator, reseller, or installer in any industry.

Process of Assembly Wire Harness

Company investing in these machines to increased productivity, which, in turn, leads to greater profits and improve efficiency.

HC-608F3 -Cable Wire Stripping Machine 35mm2

|

Specifications: Power: 220V/500W Frond end stripping length: Sheath cable wire MAX 300mm Electric cable wire MAX 30mm Rear end stripping length : Sheath cable wire MAX 180mm Electric cable wire MAX 50mm Conduit diameter: 1-12mm Productivity : 1000PCS/h Air pressure: 0.5-0.75mp |

HC-2BT+D -Multi-Core Wire Stripping Crimping Machine

|

Specifications: Power:220V50/60HZ Electricity Consumption:50W Stripping Capability: Minimum stripping length 20 mm of 2 cores wire, 35mm of 3 cores wire,40mm of 5 or more cores wire |

Wire Stripping, Cutting and Crimping Machine

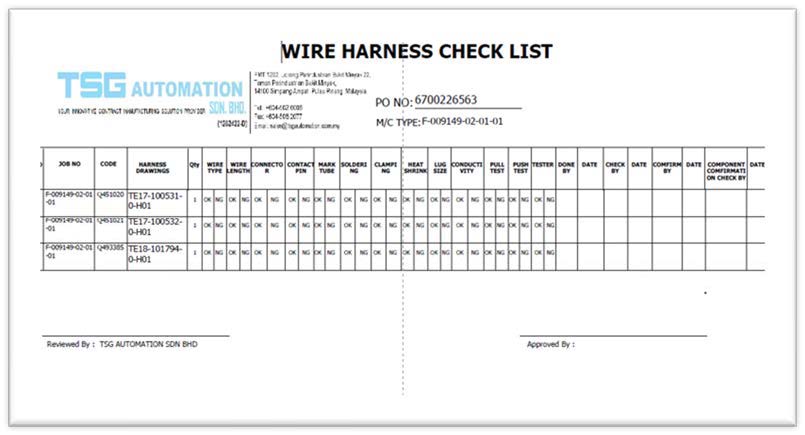

The general manufacturing process of wiring harnesses includes incoming inspection, raw material storage, wire cutting, crimping, ultrasonic welding, shrinkable heat tubing, stranded wire, terminal insertion, assembly covers and accessories (felt, tape, PVC pipe, corrugated pipe, Staples, cable ties and brackets, etc.), assembly, wiring harness inspection (appearance, size, electrical performance and air tightness, etc.), we also use checker with master cable to inspect wire harness, packaging and storage.